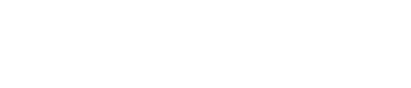

Specification: LK-FCS-R-3-25 31/35,LK-FCS-R-3-25 37/41,LK-FCS-R-4-25 31/35,LK-FCS-R-4-25 37/41

Category:

Keywords:

- 产品描述

LK-FCS-R Grating saddle clip

-

- Commodity name: LK-FCS-R Grating saddle clip

- 品号: 3001006,3001007,3001008,3001009

- 规格型号: LK-FCS-R-3-25 31/35,LK-FCS-R-3-25 37/41,LK-FCS-R-4-25 31/35,LK-FCS-R-4-25 37/41

- 材质: S31803/1.4462/2205/SS316L

- 基材厚度/高度: Height: 31-35,37-41,31-35,37-41

- 包装: 100

Grating saddle clip with tensile and shear resistance

Product No. Specification Height(mm) Material Package 3001006 LK-FCS-R-3-25 31/35 31-35 S31803/1.4462/2205/SS316L 100 3001007 LK-FCS-R-3-25 37/41 37-41 S31803/1.4462/2205/SS316L 100 3001008 LK-FCS-R-4-25 31/35 31-35 S31803/1.4462/2205/SS316L 100 3001009 LK-FCS-R-4-25 37/41 37-41 S31803/1.4462/2205/SS316L 100

Technical Data

Application: Grating fastening Minimum thickness of base material (steel): 6mm Corrosion protection: duplex stainless steel,Stainless steel 316L,or equivalent, Environmental Conditions: Dry indoor, Indoor with temporary condensation, Outdoor temporary applications, Outdoor with low pollution, Outdoor with moderate concentration of pollution, Coastal areas, Outdoor,Marine environment, areas with heavy industrial pollution,Close proximity to roads Material: S31803/1.4462/2205/SS316L Product Features

1. Body with special key design to provide excellent robustness

2. Grating fastener with tensile and shear resistance capacity

3. Two versions – grating fastening saddle with three ears for rectangular grating, or four ears for square grating

4. Size suitable for most common grating sizes

5. Tightened with a standard M8 nuts– for ease, speed and reliability

Applications

1. Fastening grating in shear-relevant zones

2. Fastening grating subject to equipment movement, e.g. trolley zone

3. Fastening grating vertically, e.g. during transportation and launch

Installation Steps

LKX-BT-GR Flat Head Stud LK-FCM-R Grating Disc System LK-FCS-R Grating Multi-Directional Clip System

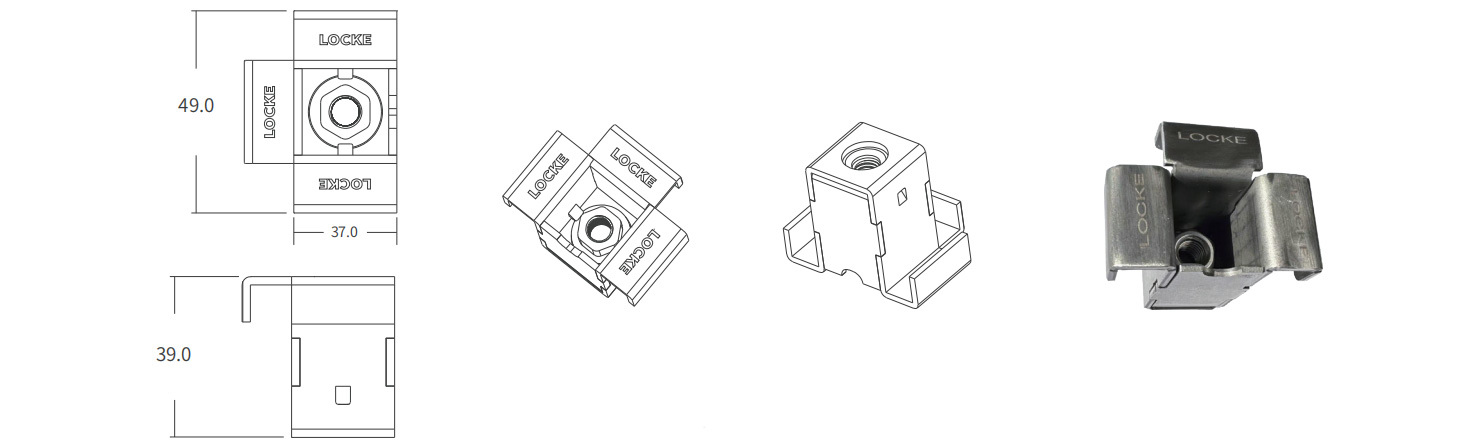

1

Use a high speed electric drill and the special drill bit to drill on the steel base material.

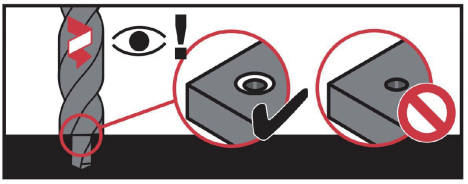

2

Use the special nail gun to shoot the flat head threaded stud (LKX-BT-GR-M8) into the holes.

3

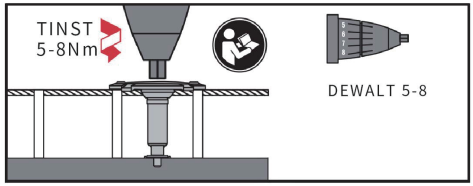

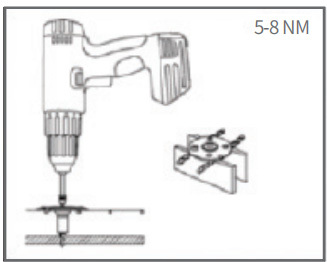

Use an electric driver to fix the grating disc (LK-FCM-R) or the stainless steel multi-directional clip (LK-FCS-R) on the exterior threads of the LKX-BT-GR-M8 flat head stud until the steel grating is fastened and the fastening torque is reached.

LK-GF Spike Nail LK-FCM-F Grating Disc System LK-MGF Grating M Type System

Use a special nail gun (powder-actuated) to shoot the threaded spike nail (LK-GF-M8) into the base material.

Use an electric driver to fix the grating disc (LK-FCM-R) on the exterior threads of LK-GF stud until the steel grating is fastened and the fastening torque is reached.

Grating Fastening

Installation of threaded spike nail

Installation of fastener discs

Related Products

Products Inquiry